Resin Transfer Molding (RTM) is a technology widely used to create products requiring a high-quality finish on both sides with a high fiber-resin ratio, while allowing a high-volume production output without sacrificing product quality and consistency. [Female Mold] Based on the reduced labour demands and time investment RTM is the preferred choice for low-cost / high volume production processes.

Resin Transfer Molding (RTM) is a technology widely used to create products requiring a high-quality finish on both sides with a high fiber-resin ratio, while allowing a high-volume production output without sacrificing product quality and consistency. [Female Mold] Based on the reduced labour demands and time investment RTM is the preferred choice for low-cost / high volume production processes.

The Resin Transfer Mold Process

The Resin Transfer Mold Process

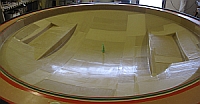

The RTM process requires 2 separate molds – one male and one matching female counter-mold. On the female tool a pre-cut fiberglass layer is applied . Hydraulic pressure or vacuum is then used to force the male tool into the female mold.

Once secured, a vacuum and/or pressure system is utilized to force resin through the fibers into the mold. [Finished Product]

The hardened and finished product is then removed, cleaned, polished, and ready for shipping.

The hardened and finished product is then removed, cleaned, polished, and ready for shipping.

During the planning process we work closely with our customer to ensure high-quality products within the required specifications.