Tooling Concepts & Design

Tooling Concepts & Design

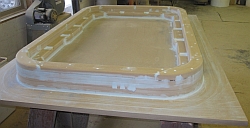

Tooling begins with the creation of a wooden copy matching the finished product. The surface of this form is carefully detailed and polished to precise dimensions and coated with a filled polyester resin. Special tooling resin and glass systems are then used to create a reverse surface image, reinforced by wood or steel to maintain its original style and shape. If necessary additional sub-assemblies are created and attached to this mold. To ensure the best quality of the final product, special attention and care is given to meet highest standards in polishing and finish.

The production mold is critical for the quality of the finished product. With our highly trained and experienced personnel Performance Poly-Tek is able to meet the most qualitative demands of our customers, regardless of size, shape, and complexity of the mold design.

The production mold is critical for the quality of the finished product. With our highly trained and experienced personnel Performance Poly-Tek is able to meet the most qualitative demands of our customers, regardless of size, shape, and complexity of the mold design.

Especially during the initial stages we are working closely with our customers to turn ideas and concepts into reality – quick, precise, reliable, and professional.

Contact us for a free consultation and quote.